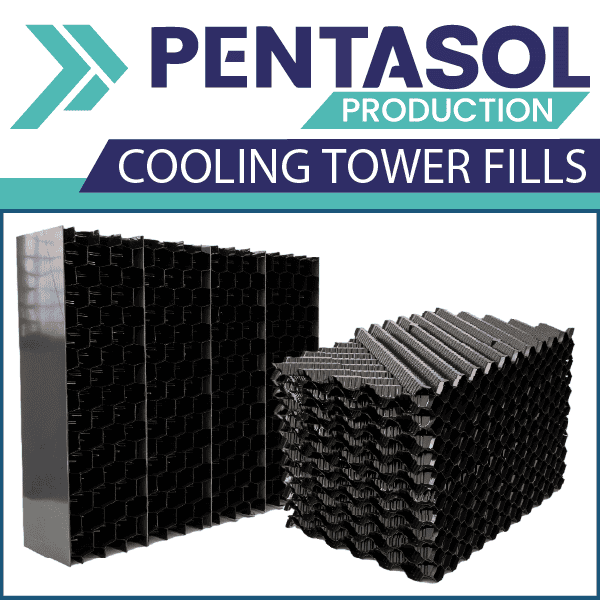

Penta cooling tower fill

Cooling tower fills is designed to maximize contact between water and air by providing a large surface area for water to spread. This contact enhances the evaporation process, which is the primary mechanism by which cooling towers dissipate heat. According to our wide range of Penta cooling tower fills, the most optimal filling for the project is installed, which optimizes costs in addition to cooling efficiency.

Penta drift eliminator

Drift Eliminator is one of cooling tower parts and above the water distribution system and fills. The main function of drift eliminators is to capture and separate water droplets from the air stream before it is leaves the cooling tower and also prevents the departure of chemically contaminated water into the environment. The dividing elements between the glued layers form a solid block, which makes handling, transportation, and installation of the drip separator easy.

Penta GRID 65 dirt-catching panel

Thanks to the design of the Penta GRID 65 dirt-catching panel and its ribbed surface, it prevents water from escaping the system, and pro a continuous incoming air flow. Prevents environmental contaminants from entering the cooling tower, such as leaves, tree branches, municipal waste or other small, medium, or large contaminants.

Our company manufactures cooling tower fills with different channel heights and designs, in standard and individual sizes. Penta cooling tower fills ensure turbulence-free, quiet operation in addition to maximized evaporation and cooling efficiency. Due to our Hungarian factory, site and warehouse, we can satisfy the customer’s needs regarding the following cooling tower fills, drift eliminators in the shortest possible time:

Penta Fill 14 cooling tower fill

Penta Fill 20 cooling tower fill

Penta Fill X20 cooling tower fill

Penta Cross Fill cooling tower fill